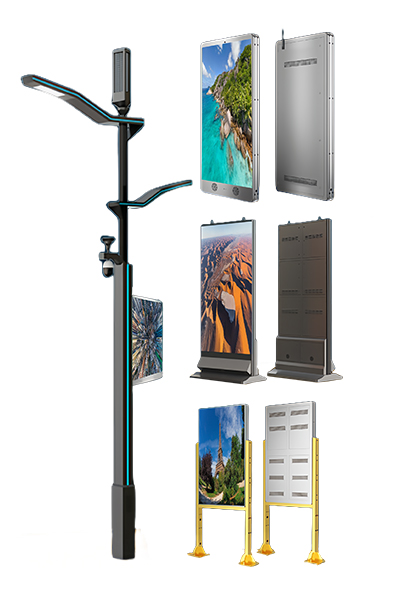

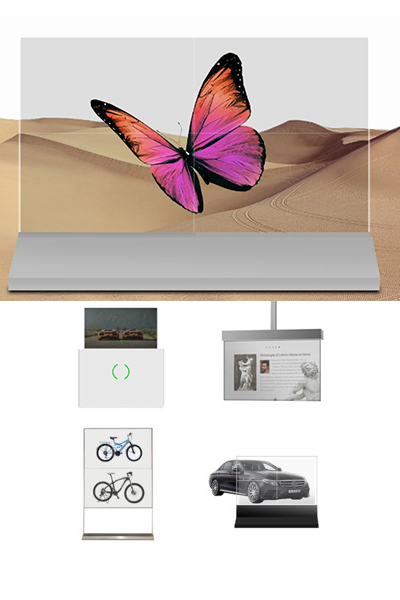

PRODUCT SERIES

PRODUCTS

ABOUT US

COMPANY PROFILE

Countries and regions are covered

100+

Researchers are employed

30+

Devices sold worldwide

600000+

Provide odm/oem services

200+

Successful cases

Solutions

Modern warehouse sorting operations depend on industrial control computers to manage package flow with precision. These systems integrate data from barcode scanners, RFID readers, and dimensional weig

Lithium-ion battery production begins with electrode fabrication, where industrial control computers orchestrate complex interactions between coating, drying, and calendaring equipment. These systems

Photovoltaic module manufacturing involves multiple interconnected processes requiring precise timing and resource allocation. Industrial control computers serve as the central nervous system, synchro

Blast furnace operations generate extreme thermal conditions that demand specialized data acquisition systems. Industrial control computers must capture temperature readings from multiple zones within

Chemical manufacturing facilities operate in zones classified by explosive risk levels, requiring industrial control computers to meet stringent safety standards. These systems must carry certificatio

3C electronics assembly demands micro-level accuracy when handling components like integrated circuits, camera modules, and battery connectors. Industrial control computers coordinate high-speed pick-

Automotive production lines demand precise timing and synchronization across multiple operations. Industrial control computers serve as the central nervous system, managing robotic arms, conveyor syst

Industrial control computers rely on fault alarm linkage mechanisms to maintain operational safety and efficiency. These systems detect anomalies through sensors and trigger appropriate responses, ran